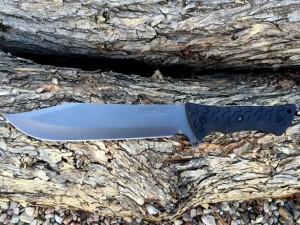

Schrade SCHF45 Leroy Fixed Blade Bowie Knife Reviewed

Marketing from Schrade

Schrade’s Leroy Full Tang Fixed Blade Knife, Titanium Coated 8Cr13MoV High Carbon Stainless Steel Bowie Blade Featuring Finger Guard and Choil, TPE Handle Slabs with Finger Grooves and Lanyard Hole, Nylon Fiber Belt Sheath

Manufacturer: Schrade, www.schrade.com

Model: SCHF45Overall Length: 16.49″ (41.88)

Blade Steel: Titanium Coated 8Cr13MoV High Carbon Stainless Steel Blade

Blade Length: 10.35″ (26.29 cm)

Blade Thickness: .20″ (5.15 mm)

Handle Material: TPE Handle Slabs with Finger Grooves

Handle Length: 6.14″ (15.60 cm)

Weight: 1.31 lbs. (20.96 oz)

Accessories: Nylon Fiber Belt Sheath with Grommet Holes

Warranty: Limited Lifetime Warranty against any manufacturing defects

Origin: China

UPC: 044356224796

MSRP: $75.00

The Review

I just received Schrade’s latest chopper, the SCHF45 Leroy the other day… Last year it was the release of their massive recurved blade, the SCHF28 Little Ricky that had everyone talking. Now with the release of the enormous 16-1/2-inch SCHF45 Leroy Fixed Blade Bowie Knife, it takes Schrade’s big-blade designs to a whole new level. Is it a knife, or is it a beast? Read on for the answer to that question…

Initial Thoughts

When I first picked up the box, I wondered if it could have been one of those new machetes that I’ve been wanting to try out. Then once I opened the box, I realized just what I had in my hands as I pulled it out and began my initial inspection.

The first thing that came to mind as picked it up and pulled it out of the sheath was that iconic scene from Crocodile Dundee… “Now that’s a knife!” This thing is huge. I must admit that its broad bowie profile is rather attractive, yet a little intimidating to look at. It is very well-balanced and quite comfortable in hand for its massive size and weight.

The nylon-fiber belt sheath is extremely durable and protects the SCHF45 when not in use. It is held firmly in place with a hook and loop strap allowing only a minimal amount of rattle due to its large size. The molded belt loop is capable of accommodating an 1-3/4″ belt and there are grommet holes and 1-1/4″ strap slots along each side providing ample lashing options.

The SCHF45 features an enormous titanium-coated 8Cr13MoV high carbon stainless steel blade a little over 10-inches long. It has a clip-point and an attractive swedge along the blade’s spine, reminiscent of a traditional bowie blade profile. The broad blade pattern adds quite a lot of heft to the blade which translates into an enormous amount of chopping power.

The full-tang is covered by two removable black textured TPE slabs with two lanyard holes at either end. The TPE handle combines an attractive non-slip groove pattern with an an ergonomic shape that is both comfortable and easy to wield in any weather condition.

The jimping on the thumb-ramp adds traction and the finger choil in front of the finger guard are perfect for choking up on the blade when you need increased blade control.

Features

Now lets focus on Leroy’s features in more detail…

The Blade

Like the SCHF28, the SCHF45 is also made from a solid slab of 8Cr13MoV high carbon stainless steel from the tip to the butt of the handle. Its massive 5mm-thick stainless steel blade and full-tang design provide the superior strength and rigidity that you would expect from a good survival chopper.

8Cr13MoV is a Chinese stainless steel that is similar in quality to AICHI, AUS-8 and 440B stainless steels with regard to strength, hardness, corrosion resistance and edge retention. Stainless steel is a popular class of material for knife blades because it has properties that are commonly resistant to rust and corrosion, while remaining easy to maintain. This makes it an excellent choice for a survival blade. While this alloy is typically easier to sharpen than other stainless alloys like 440C, it generally does not hold an edge quite as well.

While 8Cr13MoV high carbon stainless steel is certainly tough enough to withstand aggressive use, it is only rust resistant and not entirely rust proof. Even with the protective titanium coating, it is still susceptible to rust without proper care and maintenance. If the blade becomes wet, simply dry it thoroughly and lightly coat it with a protective oil like Break-Free CLP before storage and it will likely last you a lifetime.

The SCHF45’s clip point design is patterned after the iconic bowie knife, one of the most common blade shapes ever made. It is designed to provide maximum penetration when thrusting and piercing. Clip point blades give the appearance of having the forward most section of the blade from the spine to the tip point “clipped” off in a straight or concave line. Additionally, the SCHF45 has a subtle swedge ground into the blade effectively increasing the angle toward tapered point, further improving its ability to stab and pierce.

The SCHF45’s clip point design is patterned after the iconic bowie knife, one of the most common blade shapes ever made. It is designed to provide maximum penetration when thrusting and piercing. Clip point blades give the appearance of having the forward most section of the blade from the spine to the tip point “clipped” off in a straight or concave line. Additionally, the SCHF45 has a subtle swedge ground into the blade effectively increasing the angle toward tapered point, further improving its ability to stab and pierce.

The SCHF45 has a deep, hollow-grind and a slight compound bevel without any serrations. This is a very common grind on factory knives today that is simple to sharpen and easy maintain.

Jimping is the term used for describing the small notches typically cut into the spine of a blade to prevent finger-slippage while wielding the blade. The SCHF45 has thirteen notches aggressively cut into the thumb-ramp located on top of the handle. However, in this case the jimping is a little too aggressive for my taste.

The SCHF45 also has a large finger choil located just in front of the finger guard for a wide variety of gripping options. The blade’s spine near the handle and the choil are both fixed at 90° angles with squared edges, perfect for striking a ferro rod, with or without the protective coating.

The Handle

The SCHF45 is also sporting the same attractive TPE handle as that of the SCHF28. It is a hard, durable rubber with an attractive grooved pattern providing an excellent non-slip grip even in wet conditions. Thermoplastic Polyester Elastomer (TPE), sometimes referred to as thermoplastic rubber is made from a mix of plastic and rubber polymers providing both thermoplastic and elastomeric properties.

The two halves of the TPE handle are attached through the full-tang blade with two recessed allen bolts threaded directly into the knife steel allowing it to absorb much of the shock while chopping and batoning, thereby reducing fatigue. The handle is shaped with three finger cut-outs, tapered ends and a moderate palm-swell making it easy and comfortable to wield with or without gloves.

The SCHF45 also has two lanyard holes located at either end of the handle. One near the finger guard just behind the choil, and the other at the base of the handle. Each are sized perfectly for a paracord lanyard to provide a variety of tethering options.

The Sheath

The SCHF45’s rugged belt sheath made from a moulded nylon-fiber for extreme durability. The SCHF45 fits snuggly in place with only a slight amount of rattle with or without the hook and loop strap holding it down. Its molded belt loop is capable of accommodating a belt up to 1-3/4″ wide. Plus there are five grommet holes on one side, six grommet holes on the other, and four 1-1/4″ strap slots on each side of the sheath to accommodate many lashing options.

Functional Testing

Now lets see what Leroy can do… In order to provide a some sort of apples-to-apples comparison between blades, I will be performing five durability tests; Batoning, Chopping, Feather Stick, Tip Strength and Edge Retention. In a survival situation, all resources are fair game. However, since I am not in a life-or-death situation, I’ll stick to some dead wood that I have lying around for these tests.

Batoning

Per Wikipedia: Batoning is the technique of cutting or splitting wood by using a baton-sized stick or mallet to repeatedly strike the spine of a sturdy knife, chisel or blade in order to drive it through wood. The batoning method can be used to make kindling or desired forms such as boards, slats or notches. The practice is most useful for obtaining dry wood from the inside of logs for the purpose of fire making.

Out of all of my usual tests, this is the one that I am always concerned with on blades with a swedge. Sure they look great… But it usually translates into a very thin spine which is far from ideal for batoning. For this test I found a baton about 2.5″ in diameter and 18″ long.

The first part of the baton test that I typically perform on large blades consists of splitting a few logs approximately 4″ in diameter into small kindling. First in half, then quartered, and so on striking each end of the blade’s spine until I was left with a decent-sized pile of small kindling. The broad handle and 16.5″ overall length provide an enormous amount of control over the blade as it makes its way through the material when used with a baton.

For the second part of this test with larger blades, I usually try to split some larger material around 12″ tall and 12″ in diameter to demonstrate its durability. Splitting larger material with a small axe or blade is typically performed by sectioning off slices approximately 1-2″-thick from around the outer-edge of the log, parallel to the outermost rings. Then split them down further as necessary.

As I made my way around the stump along the outer edge striking each end of the blade’s spine with the baton, the SCHF45 performed exceptionally well and remained very controllable with each strike. As long as you take your time and avoid being too aggressive with the amount of material, the SCHF45 splits through the material quite well. The blade profile and deep hollow-grind are very well-suited for splitting material. However, the narrowed spine is not conducive to batoning resulting in the baton breaking repeatedly throughout the process.

As I made my way around the stump along the outer edge striking each end of the blade’s spine with the baton, the SCHF45 performed exceptionally well and remained very controllable with each strike. As long as you take your time and avoid being too aggressive with the amount of material, the SCHF45 splits through the material quite well. The blade profile and deep hollow-grind are very well-suited for splitting material. However, the narrowed spine is not conducive to batoning resulting in the baton breaking repeatedly throughout the process.

Chopping

To test the ability of the SCHF45 as a chopper, I decided that I would try bucking a 6″ log after knocking some smaller stuff off while delimbing it. At 1.31 pounds, its broad blade and stout tang generate a tremendous amount of force with each swing which translates directly into pure chopping power. As a result, the SCHF45 easily cut through the smaller limbs, often with only a single swing making delimbing the branch a quick and easy process.

To buck the log after delimbing it, you simply strike the log at a 45° angle from two perpendicular directions along the cut-line, effectively making a “V” in the material used to be, otherwise known as the kerf. The kerf should equal the diameter of the limb or trunk, and when cutting from both sides, the kerf would essentially be half diameter.

The SCHF45’s aggressive blade pattern and deep hollow-ground edge coupled with its impressive weight and balance make it a very effective chopping tool. With each swing, the SCHF45 bites deeply into the material causing the chips to go flying. Perfect for handling smaller material, and as good as any small handaxe that I’ve used of similar weight on larger material.

Feather Stick

Per Wikipedia: A feather stick (sometimes referred to as a fuzz stick) is a length of wood which is shaved to produce a head of thin curls protruding from the wood. It is used for damp wood to start a fire (or campfire) when dry tinder is hard to find.

The next test was to create a feathered stick with the SCHF45. However, with a big blade like this one, it is typically not one of the easier tasks to perform. The level of blade control necessary to finely shave the feathered curls from a stick typically degrades as the size and weight of the blade increases.

For this test, I used a 16″ stick about 2″ in diameter. First, I choked up on the blade using the finger choil and stripped off all of the outer bark from about 8″ down to the end before shaving any curls.

Once I began shaving curls from around the stick, I started about 6″ up and tried to keep them as long and as fine as I could. I tried various areas up and down the edge of the blade until I found a sweet spot near the middle of the blade. I also tried using two hands, one on the handle, the other on the spine of the blade, and the stick pinned between my workspace and my chest which worked rather well. The SCHF45 is certainly sharp enough out of the box to feather a stick, though I felt like it could use a little tuneup to smooth out the curls.

Once I began shaving curls from around the stick, I started about 6″ up and tried to keep them as long and as fine as I could. I tried various areas up and down the edge of the blade until I found a sweet spot near the middle of the blade. I also tried using two hands, one on the handle, the other on the spine of the blade, and the stick pinned between my workspace and my chest which worked rather well. The SCHF45 is certainly sharp enough out of the box to feather a stick, though I felt like it could use a little tuneup to smooth out the curls.

Tip Strength

To test the SCHF45’s ability to stab and pierce without damaging the tip, I drove the end of the blade into the end of a 12″ diameter stump as hard as I could. Then I loosened it using a side-to-side motion until it was loose enough to pull out. I repeated this a few more times just for good measure.

Next, I used the SCHF45 to bore a cone-shaped hole into the side of a small log approximately 1″ in diameter and about 1″ deep by twisting the blade until the hole was deep enough. Even with the thinning of the tip due to the clip-point and swedge, the blade and tip are certainly tough enough to handle this task without issue.

Finally, I decided to throw it at a tree stump from about 10′ away just to see if I could get it to stick… And boy did it ever (most of the time at least). The SCHF45 is well-balanced and certainly not too heavy for throwing. After a few more throws, I thought I had better stop. I was having far too much fun and I didn’t want to break it unnecessarily doing something stupid…

Edge Retention

After all of the other functional testing had been completed, the final test for the SCHF45 was to slice through a single-sheet of paper to demonstrate the edge retention. It easily survived all tests without any sign of cracks, chips or other imperfections of any kind on the blade or tip with the exception of some slight wear on the blade’s protective coating and remained sharp enough to chop wood and feather a stick throughout the entire process. However, after chopping through so much wood, it did need quick tuneup with a stone or diamond sharpener to cleanup the edge and get through a sheet of paper cleanly.

Final Thoughts

Schrade’s new SCHF45 is an enormous chopper made from a massive 1.3 pound slab of 8Cr13MoV stainless steel nearly 16.5″ long and 2.25″ at its widest point for rock-solid durability and amazing chopping power. Its broad blade and deep hollow-grind are perfect for aggressive removal of material, it really is a beast. It is quite ergonomic and very well-balanced providing exceptional blade control and reduced fatigue making it extremely comfortable to wield for extended periods of time. Perfect qualities for a real chopper.

While it’s bowie-style profile is certainly an attractive feature and the clip-point and swedge slightly reduce the overall weight of the blade and greatly improve its ability to stab and pierce. The tradeoff is not having a flat, 90° spine. Therefore, it is not ideal for bushcraft tasks like batoning and prying. However, if you can get past breaking a baton every so often, it likely won’t bother you much.

After spending some time with Leroy, I would certainly consider this chopper a sound alternative to carrying a small hatchet. I was easily able to chop through the same material with a similar level of effort, plus the SCHF45 can perform tasks that you likely wouldn’t even attempt with a hatchet. However, I would like to point out that the SCHF45 does not feature a pommel so hammering on nails and tent stakes are probably not tasks that you would attempt with it.

Rough, tough and mean enough to get the job done without having to spend a boat-load of cash. The SCHF45 is definitely serious contender for a coveted spot in your gear bag if it’s hearty blade does not scare you off. I think a lot of you will like it just as much as I do. Two thumbs up Schrade!

Look for it on Amazon in the coming weeks… I’ll post the link and add the video as soon as they become available.

You can find this and other Schrade products here: http://amzn.to/2c0kjZF

![]()

About Taylor Brands and Schrade Cutlery

Founded by Stewart Taylor in 1975, Taylor Brands has been manufacturing, designing, and distributing high-quality stainless steel cutting tools and accessories since our inception. Taylor Brands owns and produces Schrade, Old Timer, Uncle Henry, and Imperial branded products, and are also licensed to produce multiple product lines under the world famous Smith & Wesson brand. In total Taylor Brands manufactures several hundred different products including fixed and folding knives, collapsible batons, tactical pens, handcuffs, tactical and survival accessories, and flashlights.

Founded by Stewart Taylor in 1975, Taylor Brands has been manufacturing, designing, and distributing high-quality stainless steel cutting tools and accessories since our inception. Taylor Brands owns and produces Schrade, Old Timer, Uncle Henry, and Imperial branded products, and are also licensed to produce multiple product lines under the world famous Smith & Wesson brand. In total Taylor Brands manufactures several hundred different products including fixed and folding knives, collapsible batons, tactical pens, handcuffs, tactical and survival accessories, and flashlights.

--